Misalignment issues can cause a lot of vibrations in rotating machines. This information has been studied and declared by Texas A&M's OAK Trust study. In reality, reliability equipment dealer VibrAlign reported that one of its customers observed that simply over half of their plant's machinery became misaligned to a few diplomas. So, why is shaft alignment so important to be done?

While misalignment has no impact on motor efficiency in terms of quantity, correct alignment ensures you've got a clean and green electricity transmission from the motor to the pushed device. This information is per an analysis of motor shaft misalignment using the University of Tennessee's Maintenance and Reliability Center (MRC). Miss alignment creates too many vibrations that can negatively impact the mechanical seals, packing and couplings, bearings. Because of such factors, the lifespan of the rotating equipment is greatly impacted. Some other common problems that may occur due to miss alignment issues include:

- Reduction or loss of production.

- More requirements of repairs.

- There will be an increase in the sales of spare parts.

- Last but not least, it results in low-quality products.

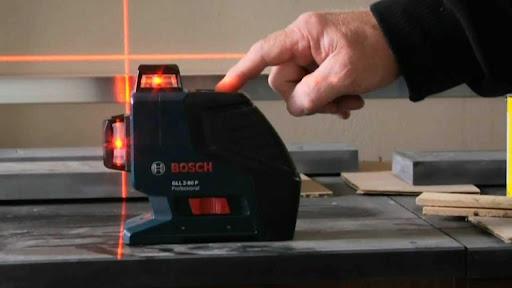

To solve the problems related to misalignment, it is important to have a laser alignment tool like Bosch GLL 3-80, which is one of the highest quality tools present in the market.

Types of Misalignments

Normally, laser alignment tools like Bosch professional 360 laser check for three types of misalignments: parallel, angular, and combination misalignment.

Parallel Misalignment

This type of misalignment usually occurs when the center of the two shafts is parallel, and they are not in the same line. These shafts then get offset in the horizontal position, which means either to the left or right, or they may be offset vertically, meaning they're located at extraordinary heights.

Angular Alignment

Angular misalignment occurs whilst the motor is offset at a perspective concerning the pushed gadget. For instance, in case you were to draw an imaginary line from the centerline of the motor shaft and the centerline of the driven system shaft, the two lines might ultimately go as opposed to run alongside a commonplace centerline. The misalignment can be either vertical or horizontal. This kind of misalignment can motivate measurable damage to both the motor and driven system shafts through the years.

Combination Misalignment

Combination misalignment occurs from the mixture or combination of both parallel and angular misalignment.

Components of Laser Alignment Tools

The alignment of the two couple shafts is the ultimate goal of any laser alignment tool like a Bosch GLL 3-80. These tools consist of straight edge, optics, and dial indicators, making them better than traditional tools. These laser alignment tools consist of the following components:

Laser Alignment Sensors

You will find the sensors of laser alignments at the shaft, flywheel, coupling, hub, or brake disc. There are two types of sensors: stationary and movable. The stationary sensors will be attached to the stationary machine, and the movable sensor will be attached to the portable machine.

Brackets

The brackets help in mounting the sensors to the machine. There are multiple brackets like magnetic brackets, non-magnetic V-brackets, v-brackets with sliding wheels and offset brackets.

Extension Chain

Extension serves to secure the sensors on the shafts and provides room for adjustments in case the sensors are too large in diameter.

Extension Rods

To keep the laser path straight and undisturbed, use extension rods to align the shafts with bigger couplings.

Display Unit

The display unit indicates alignment statistics in real-time as the laser alignment tool takes readings. Most show devices consist of integrated software, LCD monitors, rechargeable batteries, memory storage, wi-fi connectivity, and greater. Many laser alignment gears include cellular apps that connect to the device using Bluetooth and display facts in real-time on cell devices. That connects to the device the use of Bluetooth and displays facts in real-time on cell devices.

Conclusion

The primary purpose of the above discussion was to pinpoint what misalignment means. We identified the different types of misalignments that can occur and how each of them is identified to be clear on which alignment tool you need to purchase. Among the highest quality laser alignment tools is the Bosch laser line. They have an extensive line of these laser alignment tools that perform effectively and efficiently for their prices. You can compare and contrast the characteristics of different types and prices of laser alignments online, develop alternatives and choose the best one for your requirements. Bosch laser alignment tool will provide high visibility for professional users because they can perform multiple alignments, including fast vertical and horizontal with self-leveling properties.

Also read about:

7 Heart Attack Symptoms You Cant Ignore

Terms & Conditions of term life insurance policy

What Does a Share Point Developer Do